Cold fact: How did excavators move before the central rotary joint was invented?

Those who are familiar with excavators must know that there is a central rotary joint in an excavator. It is this component that enables the excavator to move freely and rotate the upper part freely. However, have you ever wondered how excavators managed to combine rotation and movement before the invention of the central rotary joint?

In fact, the central rotary joint we see now is designed for hydraulic excavators. Before the advent of hydraulic excavators, except for a few large excavators that used electricity as power, most medium and small excavators were mechanical excavators powered by gasoline or diesel engines. To transfer the power of the internal combustion engine to various parts that needed power, these excavators adopted complex mechanical transmission devices, including transmissions, clutches, gearboxes, winches, steel cables, drive shafts, chains, etc. Unlike today's hydraulic excavators, which only need to be connected to the corresponding hydraulic actuators through pipelines.

Specifically regarding the walking mechanism, mechanical excavators typically use a vertical transmission shaft to transfer power to the chassis. This walking transmission shaft is naturally located at the center of the turntable. The upper end is connected to the internal combustion engine through a gearbox and clutch to obtain power, while the lower end uses a pair of conical gears to change direction and then transmits power to both sides of the tracks through a pair of horizontal axes. Thus, regardless of the relative positions of the upper and lower parts of the vehicle, the power can be transmitted to the chassis.

Of course, after the power reaches the chassis, it still needs to be transmitted further. The common method is to use chain transmission. A pair of chains are used to connect the transverse horizontal shaft and the sprocket on the driving wheel. Thus, when the walking transmission shaft rotates, it will drive the two driving wheels to rotate, and the excavator will move in one direction through the tracks. To move in the opposite direction, all that is needed is to change the rotation direction of the transmission shaft.

If it is to turn, like other tracked vehicles, a speed difference needs to be created between the two sides of the tracks. The horizontal transmission shaft has clutches and brakes on both sides, and the power of one side of the track can be cut off by controlling the clutches to achieve the turning.

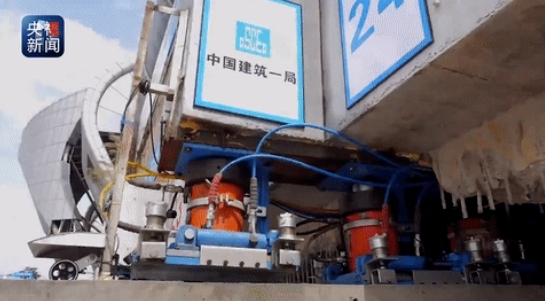

As mechanical excavators were gradually replaced by hydraulic excavators, the aforementioned transmission method also came to an end. Let me add a word about chain drive for movement. In fact, not only excavators, but also some wheeled vehicles that do not require rotation use chain drive to achieve movement. For example, some models of the Biteloros rotary drilling rigs did not adopt the chain drive system until they were acquired by Caterpillar in 2011. At that time, they switched to using the chassis of Caterpillar excavators and driving them with hydraulic motors.