Description

Nissan connecting rod PD6 PE6 RD8 RE8 RG8 RF8 China manufacturer supplier engine parts

Premium Connecting Rod from China Manufacturer for Nissan PD, PE, RD, RE, RF, RG Series Engines

◆ Product Overview

◆ Manufacturer Information

◆ Part Number & Application

◆ Product Specifications

◆ Manufacturing Advantages

◆ Quality Assurance Process

◆ Supply Chain Management

◆ Technical Support Services

◆ Market Applications

A high-quality, precision-engineered connecting rod designed for a wide range of Nissan's heavy-duty and industrial diesel engines, including the PD6, PE6, RD8, RE8, RG8, and RF8 series. This critical component from a certified China manufacturer provides an OEM-equivalent solution for engine overhauls, rebuilds, and major repairs. Engineered for durability and performance, it meets the rigorous demands of construction machinery, marine applications, and large commercial vehicles.

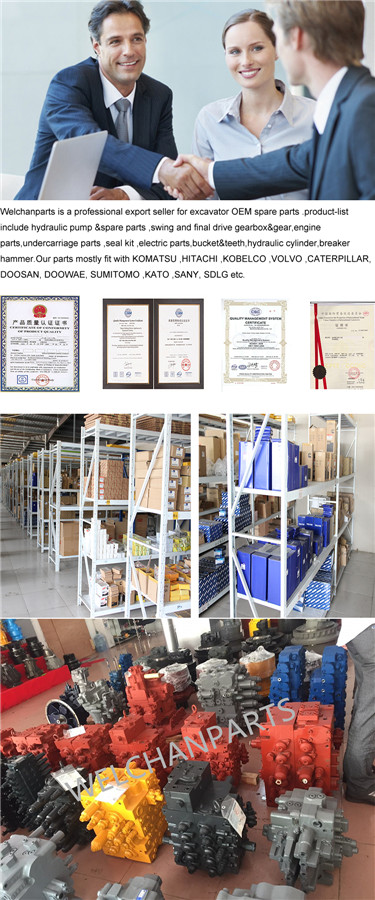

✓ Manufacturer Type: China Heavy Industrial & Marine Engine Parts Specialist

✓ Certification: ISO 9001:2015, IATF 16949 Certified

✓ Specialization: Nissan Large-Bore Industrial Engine Components

✓ Supply Model: Factory Direct to Global Construction, Marine & Power Generation Markets

✓ Compatible Engine Models: Nissan PD6, PE6, RD8, RE8, RG8, RF8 Diesel Engines

✓ Application: Major Engine Overhaul, Rebuild, and Critical Repair

✓ Primary Use: Construction Equipment (Excavators, Cranes), Marine Propulsion, Large Generator Sets, Heavy Trucks

✓ Product Type: Heavy-Duty Forged Connecting Rod Assembly

✓ Condition: 100% New, High-Quality Manufacturing

✓ Manufacturer Origin: China Precision Heavy-Duty Manufacturing

✓ OEM Reference: Engineered to Match Original Nissan Specifications for PD/PE/RD/RE/RF/RG Series

✓ Key Feature: Broad compatibility across multiple Nissan heavy-duty engine platforms

✓ Multi-Platform Expertise: Specialized knowledge across Nissan's PD, PE, and R-series large-bore engine families.

✓ Superior Forging & Machining: Utilizes advanced forging techniques and precision CNC machining for optimal strength and fit.

✓ Material Excellence: High-grade alloy steel, heat-treated for maximum durability under extreme stress and high-load cycles.

✓ Cross-Application Reliability: Validated for performance in diverse, demanding environments from sea to construction site.

✓ Quality Consistency: Rigorous process control ensures every component meets the high standards required for industrial power units.

✓ Certified material sourcing from specialized steel suppliers.

✓ Full-dimensional inspection using CMM technology against engine-specific master specifications.

✓ Precise weight matching and balancing to ensure smooth operation across all compatible engine models.

✓ Advanced surface treatments for enhanced corrosion and wear resistance.

✓ Performance validation under simulated high-load operating conditions.

✓ Production Capacity: Dedicated production lines for large industrial engine components.

✓ Lead Time: 40-50 days for custom heavy-duty forging and machining.

✓ Minimum Order: Competitive MOQ for industrial and marine parts distributors.

✓ Packaging: Heavy-duty, protective packaging for secure international freight.

✓ Logistics: Efficient global shipping to major industrial ports and equipment hubs.

✓ Comprehensive application guide for PD6, PE6, RD8, RE8, RG8, RF8 engine models.

✓ Installation guidelines and technical specifications.

✓ Construction & Mining: Critical component for overhauling engines in excavators, cranes, and drilling rigs.

✓ Marine Industry: Essential part for marine propulsion and auxiliary engine repairs.

✓ Power Generation: Key component for large industrial generator set overhauls.

Contact Us:

Whatsapp/Phone: +86158 6849 0970

Skype: robinwanguuu@hotmail.com

Email: newm9992@hotmail.com

karherine@xcgparts.com

Wechat: welchanparts_luke

Website: www.xcgparts.com