Description

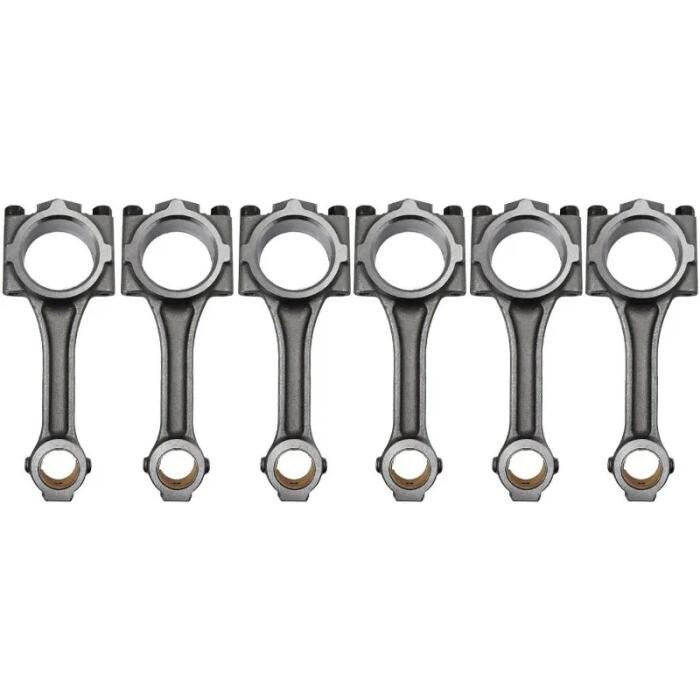

Komatsu connecting rod 6207-31-3101 6206-31-3101 4D95 6D95 engine PC60 PC100 PC200 PC200-5 China supplier

Komatsu Genuine Connecting Rod Assemblies (Parts 6207-31-3101 & 6206-31-3101) for 4D95 & 6D95 Engines – China Supplier Direct

◆ Product Overview

Genuine Komatsu connecting rod assemblies, part numbers 6207-31-3101 and 6206-31-3101, designed for Komatsu 4D95 and 6D95 series diesel engines. These critical engine components are supplied as brand new OEM-specification parts, ensuring exact fit, proper balance, and reliable performance for Komatsu PC60, PC100, PC200, PC200-5 excavators and compatible equipment.

◆ Supplier Profile

✓ Type: China Authorized Komatsu Engine Parts Specialist

✓ Focus: Komatsu D95 Series Engine Internal Components

✓ Services: Genuine Parts Supply, Technical Consultation, Small & Bulk Orders

✓ Market: Global Komatsu Dealers, Engine Rebuilders, Equipment Repair Shops

✓ Certification: ISO 9001:2015 Quality Management System Certified

◆ Part Specifications & Compatibility

✓ OEM Part Numbers:

-

6207-31-3101 (Primary Application)

-

6206-31-3101 (Compatible/Variant)

✓ Part Name: Connecting Rod Assembly (Complete with Bearings & Bolts)

✓ Compatible Engine Models: -

Komatsu 4D95 Engine (4-Cylinder)

-

Komatsu 6D95 Engine (6-Cylinder)

✓ Machine Applications: -

Komatsu PC60 Series Excavators

-

Komatsu PC100 Series Excavators

-

Komatsu PC200 Series Excavators

-

Komatsu PC200-5 Excavator

-

Other Komatsu equipment using 4D95/6D95 engines

✓ Condition: 100% New OEM-Specification Parts

◆ Product Features & Specifications

✓ Material Composition: High-strength forged alloy steel

✓ Manufacturing Process: Precision forging, CNC machining, heat treatment

✓ Design Features: I-beam construction for optimal strength and weight ratio

✓ Included Components:

-

Connecting rod body

-

Connecting rod cap

-

High-tensile rod bolts and nuts

-

Precision rod bearings (upper and lower shells)

✓ Quality Characteristics: -

Exact dimensional accuracy to OEM specifications

-

Proper weight matching for engine balance

-

Precision bearing surfaces for optimal oil film retention

-

Correct hardness and material properties

◆ Manufacturing Quality Standards

✓ Material Certification: Certified alloy steel with proper chemical composition

✓ Forging Process: Controlled forging for grain structure optimization

✓ Machining Accuracy: CNC machining within 0.01mm tolerance

✓ Heat Treatment: Controlled quenching and tempering for strength/ductility balance

✓ Surface Treatment: Phosphating or other anti-corrosion treatments

✓ Final Inspection: 100% dimensional, weight, and surface quality verification

◆ Technical Specifications

✓ Center-to-Center Length: Precise specification matching original design

✓ Big End Diameter: Exact dimension for proper bearing fit and clearance

✓ Small End Diameter: Precision sized for piston pin fit

✓ Weight Class: Marked for proper piston/rod assembly matching

✓ Bolt Specifications: High-grade bolts with defined torque/tension characteristics

◆ Complete Kit Contents

✓ Connecting rod (forged and machined body)

✓ Matching rod cap

✓ High-strength connecting rod bolts (2 per rod)

✓ Matching nuts (where applicable)

✓ Precision rod bearing shells (upper and lower)

✓ Protective packaging to prevent damage

◆ Installation Requirements & Recommendations

✓ Professional Installation: Critical component requiring skilled technician installation

✓ Required Tools: Torque wrench, micrometer, plastigage, cleaning solvents

✓ Installation Procedure:

-

Thorough cleaning of all components

-

Verification of bearing clearances

-

Proper lubrication of bearing surfaces

-

Correct bolt torque sequence and specification adherence

✓ Best Practices:

-

Replace in complete sets (all rods in engine)

-

Verify piston pin fit during assembly

-

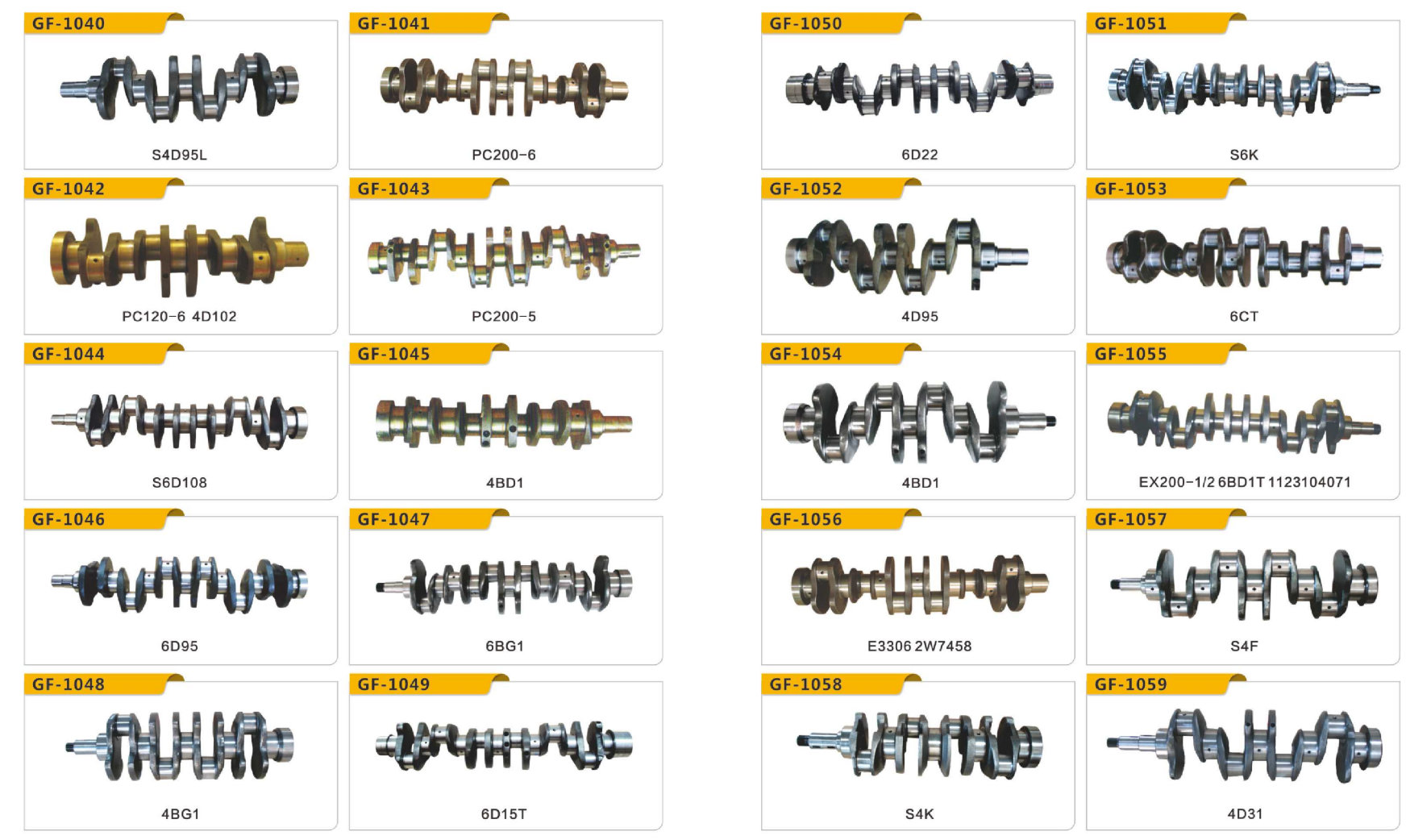

Check crankshaft journal condition before installation

-

Follow Komatsu factory service manual procedures

◆ Quality Assurance Process

✓ Dimensional Verification: All critical dimensions checked against master specifications

✓ Material Testing: Chemical composition and mechanical property verification

✓ Surface Inspection: Bearing surface finish and geometry verification

✓ Weight Matching: Weight classification to ensure engine balance

✓ Documentation: Material certificates and inspection reports available upon request

◆ Supply & Logistics

✓ Availability: Regular stock maintained for quick shipment

✓ Order Options: Available as single rods or complete engine sets

✓ Packaging: Individual protective packaging to prevent shipping damage

✓ Shipping: Worldwide delivery via air or sea freight with tracking

✓ Minimum Order: No minimum quantity – single parts available

✓ Lead Time: Typically 7-15 days for standard orders

◆ Common Applications

✓ Engine Overhaul: Essential component during complete engine rebuild

✓ Preventive Maintenance: Replacement during scheduled major service intervals

✓ Repair Operations: Replacement of damaged or worn connecting rods

✓ Performance Restoration: Critical for restoring proper engine compression and power output

◆ Customer Support Services

✓ Technical Specifications: Detailed dimensional drawings available

✓ Application Verification: Assistance confirming correct part for your engine serial number

✓ Installation Guidance: Basic procedures and torque specifications provided

✓ Bulk Order Support: Competitive pricing and logistics for quantity orders

✓ Quality Documentation: Material certifications and test reports available

◆ Important Usage Notes

✓ Critical Component: Connecting rods are safety-critical parts – never use damaged or questionable components

✓ Proper Storage: Store in clean, dry conditions with protective coating intact

✓ Pre-Installation: Always verify all dimensions and clearances before installation

✓ Torque Procedure: Follow exact torque specifications and sequences – do not estimate

✓ Bearing Clearance: Always verify bearing clearance with proper measuring tools