Introduction to Various Drilling Methods of Rotary Drilling Rigs

An excellent driller should always be clear about the type and strength of the geological formation being drilled at any given moment, and know which drill pipe and drill bit to use and what drilling method is the most effective. Only in this way can they control the operation well, minimize the load, reduce wear and tear, and achieve the fastest drilling progress.

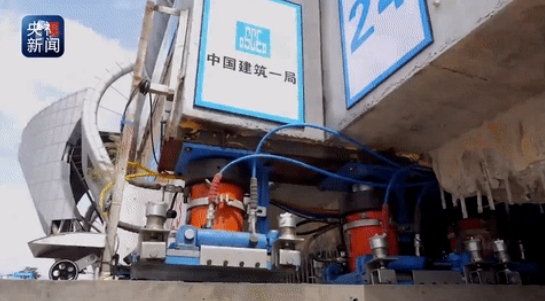

The rotary drilling machine can be classified into four drilling methods based on the geological conditions: cutting, crushing, stirring and grinding.

1. Cutting type

For cutting drilling, bucket teeth are used. A double-bottom sand-drawing bucket is combined with a friction-type drill pipe. It is suitable for drilling in relatively stable and low-resistance strata, with a general geological strength of less than 400 kilopascals, such as clay layers, silt and sand layers. Through the rotation of the bucket teeth, the resistance can be reduced and the drilling speed can be increased.

II. Fragmentation Style

Fracturing drilling uses cutting teeth for drilling. Most of them use double-bottom rock-entry drill chutes. According to the geological strength, friction-resistant or mechanical-lock drill pipes can be configured. It can drill through gravel, mudstone, sandstone, shale and moderately weathered rocks with a drilling strength of 500 kPa to 1000 kPa. Through the transmission of pressure to the alloy points on the cutting teeth, fracturing drilling is achieved.

III. Pivoting Type

Double-bottom sand extraction and double-bottom rock-entry drilling tools can be used. They can also be combined with Baomei teeth. Due to the different types of geological formations, the drilling methods also change. For example, when drilling through gravel layers, since the arrangement of the gravel is irregular and cannot be cut or broken, a rocking drilling method can be used. The main reel suspends the drill pipe, and the drill bit tip of the drill tool rocks the gravel to loosen it. Then, the drill tool is lowered and floated for further drilling. This operation method avoids the strength and vibration of the gravel.

IIII. Grinding type

Using rock drilling tubes and toothed drill bits, combined with machine-lock type drill rods for drilling, to penetrate rock layers with a calculated single-week compressive strength, ranging from several megapascals to several tens of megapascals, usually being end-bearing piles. The rock is drilled in by circular cutting and grinding at the entry point of the tube drill, or by toothed drill for drilling. At the same time, depending on the type, strength, brittleness and fractures of the rock layer, there is a possibility of fragmentation.