Description

Doosan connecting rod 6502401-6018A 65.02401-6019 China manufacturer supplier Doosan DE08 PU086T engine parts

Heavy-Duty Connecting Rod from China Manufacturer for Doosan Daewoo DE12 & D2366T Engine Series

◆ Product Overview

A premium, extra heavy-duty connecting rod engineered for the Doosan Daewoo DE12, DE12T, DE12TI, DE12TIS, and D2366T series of high-performance diesel engines. This critical component from a certified China manufacturer serves as a direct replacement for OEM part number 65.02401-6012. Specifically designed for the extreme demands of large-scale construction and mining equipment, it provides reliable power for engine overhauls and rebuilds in Doosan excavator models SH340, DH360-5, and DH420-7, ensuring maximum durability in the toughest working environments.

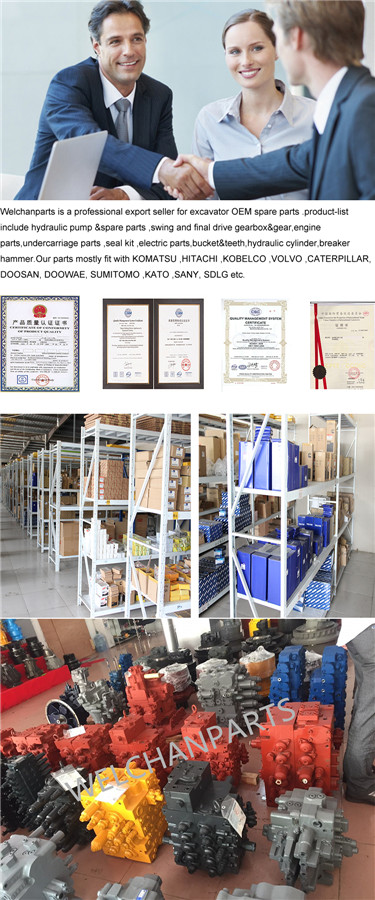

◆ Manufacturer Information

✓ Manufacturer Type: China Large-Scale Mining & Construction Machinery Parts Specialist

✓ Certification: ISO 9001:2015, IATF 16949 Certified

✓ Specialization: Doosan Daewoo Large-Bore Engine Components

✓ Supply Model: Factory Direct to Global Mining & Heavy Construction Markets

◆ Part Number & Application

✓ OEM Part Number: 65.02401-6012

✓ Engine Models: Doosan Daewoo DE12, DE12T, DE12TI, DE12TIS, D2366T

✓ Host Equipment: Doosan Excavator Models SH340, DH360-5, DH420-7

✓ Application: Major Engine Overhaul, Rebuild, and Critical Repair

◆ Product Specifications

✓ Product Type: Extra Heavy-Duty Forged Connecting Rod Assembly

✓ Condition: 100% New, Factory Direct Quality

✓ Manufacturer Origin: China Precision Mega-Manufacturing

✓ OEM Reference: Direct Replacement for Doosan 65.02401-6012 Specifications

✓ Key Feature: Engineered for high displacement, high cylinder pressure, and continuous heavy-load operation

◆ Manufacturing Advantages

✓ DE12/D2366 Platform Expertise: Specialized in components for Doosan's flagship large-bore engine series used in 30-50 tonne class excavators.

✓ Mega-Forging Capability: Utilizes large-scale, advanced forging presses for components requiring ultimate structural integrity and fatigue life.

✓ Material Superiority: Highest-grade alloy steel with specialized heat treatment for extreme stress and thermal fatigue resistance.

✓ Precision on a Grand Scale: Sophisticated CNC machining handles large dimensions and tight tolerances required for perfect assembly in high-power engines.

✓ Mining-Duty Validation: Products are tested against the most rigorous 24/7 mining and heavy quarry duty cycles.

◆ Quality Assurance Process

✓ Certified material sourcing from global leaders in ultra-heavy-duty steel forgings.

✓ Full 3D metrology and CMM inspection against stringent OEM master specifications.

✓ Meticulous weight matching and balancing to exacting standards for large-displacement engine smoothness.

✓ Advanced surface engineering including shot peening and specialized coatings for maximum wear and fatigue resistance.

✓ Performance validation under simulated maximum load and endurance cycles typical for DH360/DH420 excavators.

◆ Supply Chain Management

✓ Production Capacity: Specialized high-value production line for large excavator engine components.

✓ Lead Time: 50-60 days for manufacturing and calibration of extra heavy-duty forgings.

✓ Minimum Order: MOQ structured for major OEM service networks, large mining contractors, and construction fleet operators.

✓ Packaging: Custom-engineered heavy-duty secure packaging for international transport of high-value parts.

✓ Logistics: Specialized global freight handling for oversized components to remote mining and major construction sites worldwide.

◆ Technical Support Services

✓ Detailed application data for DE12/D2366T engine configurations in SH340/DH360-5/DH420-7 excavators.

✓ Comprehensive installation guidelines and torque specifications.

✓ Dedicated engineering support for major rebuild projects and large fleet operators.

◆ Market Applications

✓ Large Excavator Service Centers: Essential for maintaining Doosan's SH/DH series large excavator fleets.

✓ Mining & Quarry Operations: Critical component for high-production digging and loading cycles in extreme conditions.

✓ Heavy Civil Construction: Key part for major infrastructure and dam construction projects.

Contact Us:

Whatsapp/Phone: +86158 6849 0970

Skype: robinwanguuu@hotmail.com

Email: newm9992@hotmail.com

karherine@xcgparts.com

Wechat: welchanparts_luke

Website: www.xcgparts.com