Description

Doosan Daewoo connecting rod D2366 D2366T DE12 China manufacturer supplier engine parts DH360-5 DH420-7 excavator components

Heavy-Duty Connecting Rod from China Manufacturer for Doosan Daewoo D2366 & DE12 Engine Series

◆ Product Overview

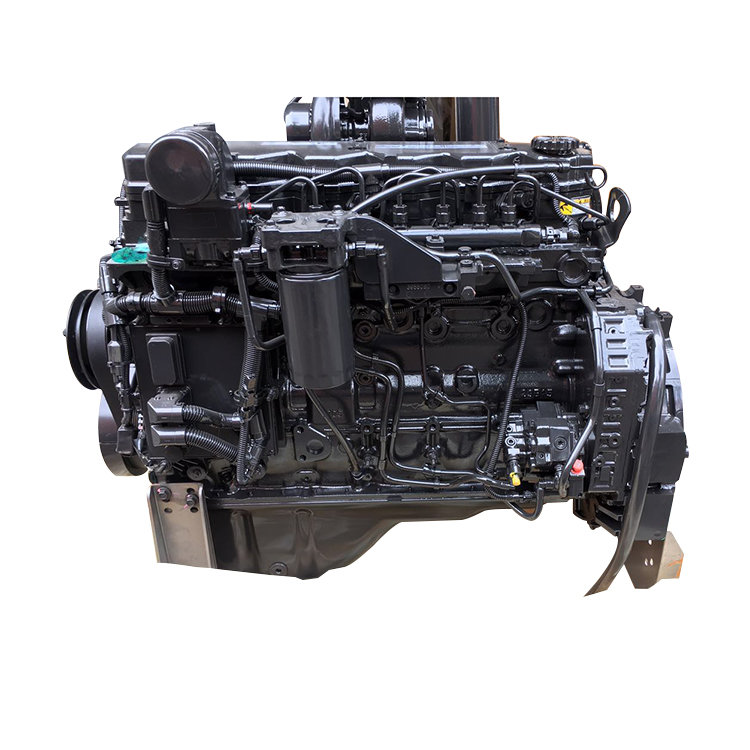

A robust, high-precision connecting rod engineered for the Doosan Daewoo D2366, D2366T, DE12, DE12T, DE12TI, and DE12TIS series of heavy-duty diesel engines. This critical component from a certified China manufacturer is designed for extreme-duty cycles in large construction machinery. It provides reliable performance for engine overhauls and rebuilds in Doosan excavator models including the SH340, DH360-5, and DH420-7, ensuring power and durability in demanding mining and construction environments.

◆ Manufacturer Information

✓ Manufacturer Type: China Heavy Construction Machinery Engine Parts Specialist

✓ Certification: ISO 9001:2015, IATF 16949 Certified

✓ Specialization: Doosan Daewoo Engine Components

✓ Supply Model: Factory Direct to Global Mining & Construction Equipment Markets

◆ Part Number & Application

✓ Engine Models: Doosan Daewoo D2366, D2366T (Turbo), DE12, DE12T, DE12TI, DE12TIS

✓ Host Equipment: Doosan Excavator Models SH340, DH360-5, DH420-7

✓ Application: Major Engine Overhaul, Rebuild, and Critical Repair

◆ Product Specifications

✓ Product Type: Heavy-Duty Forged Connecting Rod Assembly

✓ Condition: 100% New, Factory Direct Quality

✓ Manufacturer Origin: China Precision Heavy Industry Manufacturing

✓ OEM Reference: Direct Replacement for Doosan D2366/DE12 Series Specifications

✓ Key Feature: Engineered for high-torque, continuous heavy-load excavator operation

◆ Manufacturing Advantages

✓ Doosan Engine Expertise: Specialized focus on Doosan Daewoo's D2366 and DE12 engine platforms for large excavators.

✓ Premium Forging Technology: Utilizes advanced forging processes for superior grain structure and fatigue resistance.

✓ Material Excellence: High-grade alloy steel with specialized heat treatment for maximum durability under high stress.

✓ Precision Machining: State-of-the-art CNC machining ensures perfect fitment and balance for smooth operation.

✓ Mining-Duty Validation: Products are tested against the rigorous duty cycles of large excavators and mining equipment.

◆ Quality Assurance Process

✓ Certified material sourcing from mills specializing in heavy industrial forgings.

✓ Full-dimensional inspection using Coordinate Measuring Machines (CMM) against OEM master specifications.

✓ Precise weight matching and balancing critical for smooth high-inertia engine operation.

✓ Advanced surface treatments including shot peening for enhanced fatigue life.

✓ Rigorous testing under conditions simulating DH360/DH420 series excavator load profiles.

◆ Supply Chain Management

✓ Production Capacity: Dedicated high-volume line for large excavator engine components.

✓ Lead Time: 45-55 days for premium forged heavy-duty parts.

✓ Minimum Order: Competitive MOQ for construction machinery distributors and large dealers.

✓ Packaging: Heavy-duty, climate-controlled packaging for international shipping.

✓ Logistics: Specialized logistics capable of delivery to remote mining and major construction sites.

◆ Technical Support Services

✓ Detailed application guides for SH340, DH360-5, and DH420-7 excavator compatibility.

✓ Comprehensive installation guidelines and torque specifications.

✓ Engineering support for major equipment rebuild facilities.

◆ Market Applications

✓ Large Excavator Service Centers: Essential for maintaining Doosan DH series excavator fleet uptime.

✓ Mining & Heavy Construction: Critical component for in-house maintenance of high-production machinery.

✓ Global Construction Parts Distributors: High-value inventory for the Doosan excavator aftermarket.

Contact Us:

Whatsapp/Phone: +86158 6849 0970

Skype: robinwanguuu@hotmail.com

Email: newm9992@hotmail.com

karherine@xcgparts.com

Wechat: welchanparts_luke

Website: www.xcgparts.com