Description

Cummins connecting rod 6204-31-3111 4993823 B3.3 QSB3.3 Komatsu 4D95 S4D95 6D95 engine China supplier

Cummins/Komatsu Connecting Rod Assemblies (Part #6204-31-3111 / 4993823) for B3.3, QSB3.3, 4D95, S4D95 & 6D95 Engines – China Supplier Direct

◆ Product Overview

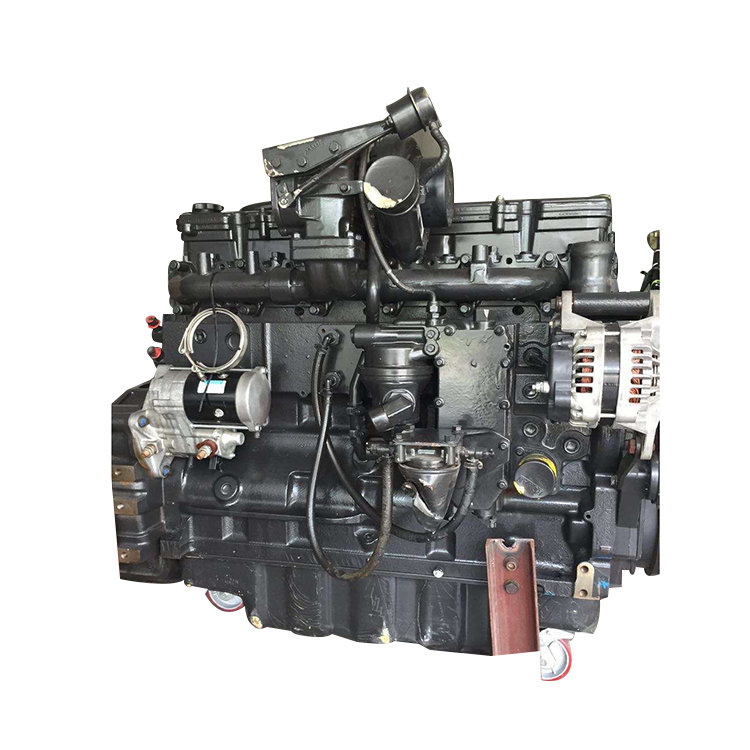

High-quality connecting rod assemblies, cross-referenced to OEM part numbers 6204-31-3111 (Komatsu) and 4993823 (Cummins), engineered for Cummins B3.3/QSB3.3 industrial engines and compatible with Komatsu 4D95, S4D95, and 6D95 engine series. These precision components are supplied as new OEM-equivalent parts, ensuring reliable performance across multiple engine platforms in construction and industrial equipment.

◆ Supplier Profile

✓ Type: China Specialist in Cross-Platform Engine Components

✓ Focus: Cummins B3.3 & Komatsu D95 Series Engine Parts Interchange

✓ Services: Genuine-Quality Parts Supply, Cross-Reference Verification, Technical Support

✓ Market: Global Engine Rebuilders, Equipment Fleets, Parts Distributors

✓ Certification: ISO 9001:2015, IATF 16949 Quality Systems

◆ Part Specifications & Cross-Compatibility

✓ OEM Part Numbers:

-

Komatsu: 6204-31-3111 / 6204313111

-

Cummins: 4993823

✓ Part Name: Complete Connecting Rod Assembly

✓ Primary Engine Applications: -

Cummins: B3.3, QSB3.3 Series Industrial & Construction Engines

-

Komatsu: 4D95, S4D95, 6D95 Engine Series

✓ Machine Compatibility: -

Equipment powered by Cummins B3.3/QSB3.3 engines

-

Komatsu PC60, PC78, PC100, PC130 series excavators

-

Various compact construction equipment and industrial machinery

✓ Condition: 100% New, OEM-Quality Manufacturing

◆ Product Features & Engineering Specifications

✓ Material: High-strength forged steel with precision alloy composition

✓ Manufacturing Process:

-

Precision die forging for optimal grain structure

-

CNC machining to exact dimensional specifications

-

Computer-controlled heat treatment for strength and durability

-

Precision grinding of critical bearing surfaces

✓ Design Features: -

Optimized I-beam design for strength-to-weight ratio

-

Precision oil passage and spray hole configurations

-

Weight-matched sets for engine balance requirements

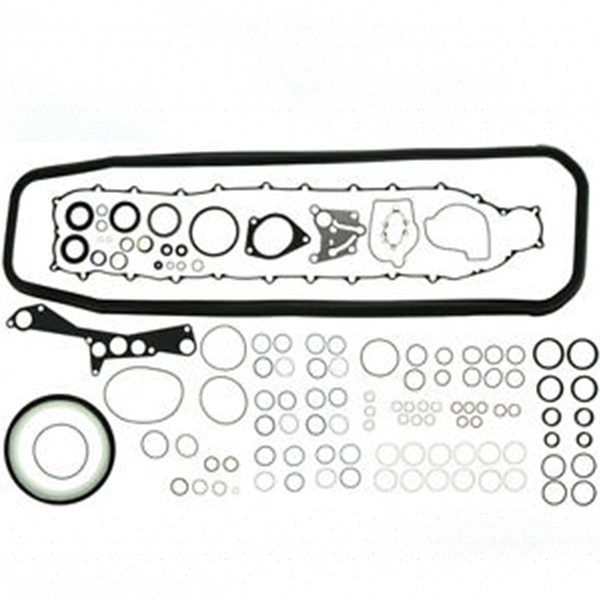

✓ Complete Assembly Includes: -

Connecting rod body (forged and machined)

-

Matched connecting rod cap

-

High-tensile strength rod bolts and nuts

-

Precision bearing shells (upper and lower)

◆ Manufacturing Quality Standards

✓ Material Certification: Documented material traceability with chemical analysis

✓ Dimensional Accuracy: CNC machining within ±0.005mm tolerance on critical dimensions

✓ Heat Treatment: Controlled quenching and tempering to achieve specified hardness

✓ Surface Integrity: Precision grinding and polishing of bearing surfaces

✓ Weight Matching: Individual rods weight-classified for proper engine balance

✓ Final Inspection: 100% dimensional, surface, and weight verification

◆ Technical Specifications

✓ Length (Center-to-Center): Precisely manufactured to original engine design specifications

✓ Big End Bore: Exact diameter for proper bearing clearance and crush fit

✓ Small End Bore: Correct size for piston pin fit (press or clearance as specified)

✓ Weight Class: Marked and verified for proper piston/rod assembly matching

✓ Bolt Specifications: High-grade metric bolts with defined torque/yield characteristics

✓ Bearing Surfaces: Precision ground for optimal oil film retention and load distribution

◆ Installation Requirements & Guidelines

✓ Professional Installation Required: Critical component demanding skilled technician installation

✓ Essential Tools:

-

Precision torque wrench (calibrated)

-

Micrometers and dial bore gauges

-

Plastigage or equivalent clearance measurement tools

-

Proper cleaning solvents and assembly lubricants

✓ Installation Procedure:

-

Complete cleaning of all components

-

Verification of bearing clearances using approved methods

-

Proper lubrication of all bearing surfaces

-

Adherence to exact torque specifications and sequences

-

Verification of piston alignment and protrusion

✓ Critical Best Practices:

-

Replace connecting rods in complete sets

-

Never reuse old rod bolts – always use new bolts

-

Verify crankshaft journal condition before installation

-

Follow manufacturer-specific service manual procedures

◆ Quality Assurance Process

✓ Dimensional Verification: All critical dimensions checked against master specifications

✓ Material Testing: Chemical composition and mechanical property validation

✓ Surface Inspection: Microscopic examination of bearing surfaces for defects

✓ Weight Classification: Precise weight matching to ensure engine balance

✓ Documentation: Material certificates, inspection reports, and compliance documentation available

◆ Supply & Logistics Information

✓ Inventory Status: Regularly stocked for immediate shipment

✓ Order Options: Available as individual rods or complete engine sets

✓ Packaging: Industrial-grade protective packaging with anti-corrosion treatment

✓ Shipping Methods:

-

Express courier (DHL/FedEx/UPS) for urgent requirements

-

Sea freight for bulk/container orders

✓ Lead Times: -

Standard orders: 7-14 business days

-

Custom/bulk orders: 20-35 business days

✓ Minimum Order: Single parts available – no minimum quantity restrictions

◆ Application Scenarios

✓ Engine Overhaul Projects: Essential component during complete engine rebuilds

✓ Preventive Maintenance: Scheduled replacement during major service intervals

✓ Failure Repair: Replacement of damaged, worn, or fatigued connecting rods

✓ Fleet Maintenance Programs: Bulk supply for equipment maintenance operations

✓ Performance Restoration: Critical for restoring proper engine compression and efficiency

◆ Customer Support Services

✓ Technical Documentation: Detailed engineering drawings and specifications

✓ Cross-Reference Verification: Assistance confirming compatibility for specific applications

✓ Installation Guidance: Basic procedures and critical torque specifications

✓ Quality Certification: Material and compliance certificates provided upon request

✓ Volume Order Support: Custom pricing and logistics arrangements for bulk requirements

◆ Important Usage & Safety Notes

✓ Critical Safety Component: Connecting rods are safety-critical parts – thorough inspection required before installation

✓ Proper Storage: Maintain in original packaging in clean, dry, temperature-controlled environment

✓ Pre-Installation Verification: Check all dimensions, clearances, and fits before assembly

✓ Torque Procedure Compliance: Use calibrated equipment and follow exact torque specifications

✓ Bearing Clearance Verification: Always verify with proper measurement tools before final assembly

Contact Us:

Whatsapp/Phone: +86158 6849 0970

Skype: robinwanguuu@hotmail.com

Email: newm9992@hotmail.com

karherine@xcgparts.com

Wechat: welchanparts_luke

Website: www.xcgparts.com