Description

Caterpillar camshaft 8N3891 7C3864 4P2942 China manufacturer supplier Caterpillar 3306 engine parts

Heavy-Duty Camshaft from China Manufacturer for Caterpillar 3306 Engine Series

◆ Product Overview

◆ Manufacturer Information

◆ Part Number & Application

◆ Product Specifications

◆ Manufacturing Advantages

◆ Quality Assurance Process

◆ Supply Chain Management

◆ Technical Support Services

◆ Market Applications

A premium, precision-ground camshaft engineered for the legendary Caterpillar 3306 industrial diesel engine. This critical component from a certified China manufacturer serves as a direct replacement for OEM part numbers 8N3891 (8N-3891), 7C3864 (7C-3864), and 4P2942 (4P-2942). Designed for durability and precise valve timing, it delivers OEM-equivalent performance for major engine overhauls and rebuilds in construction, mining, power generation, and heavy truck applications.

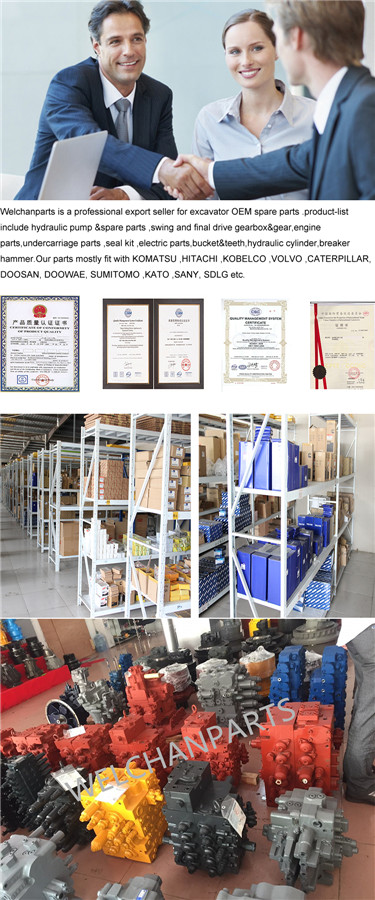

✓ Manufacturer Type: China Heavy-Duty Industrial Engine Parts Specialist

✓ Certification: ISO 9001:2015, IATF 16949 Certified

✓ Specialization: Caterpillar 3300 Series Engine Components

✓ Supply Model: Factory Direct to Global Mining, Construction & Power Gen Markets

✓ OEM Part Numbers: 8N3891 / 8N-3891, 7C3864 / 7C-3864, 4P2942 / 4P-2942

✓ Engine Model: Caterpillar 3306 Diesel Engine

✓ Application: Complete Engine Overhaul & Major Rebuild

✓ Primary Use: Construction Equipment (Excavators, Dozers), Mining Trucks, Generator Sets, Heavy-Duty Trucks

✓ Product Type: Heavy-Duty Forged & Ground Camshaft

✓ Condition: 100% New, Factory Direct Quality

✓ Manufacturer Origin: China Precision Heavy-Duty Manufacturing

✓ OEM Reference: Direct Replacement for Caterpillar 3306 Specifications

✓ Key Feature: Precision-ground lobes and journals to restore original engine timing, power, and efficiency

✓ 3306 Engine Mastery: Specialized expertise in the Caterpillar 3306 camshaft profiles, critical for engine performance and fuel efficiency.

✓ Premium Forging & Machining: Starts with a high-quality forging, followed by state-of-the-art CNC machining and precision grinding for exact lobe profiles.

✓ Advanced Heat Treatment: Utilizes precise induction hardening processes on lobes and journals to achieve optimal surface hardness and core toughness for maximum service life.

✓ Rigorous Dimensional Verification: 100% inspection of all critical dimensions, including lobe lift, base circle, journal diameters, and overall straightness.

✓ Heavy-Duty Validation: Manufactured to withstand the high-stress environment of industrial and mining applications.

✓ Certified material sourcing for premium camshaft-grade steel forgings.

✓ Complete lobe profile verification using optical comparators and CMM technology against OEM master specifications.

✓ Hardness depth and value testing on all lobes and bearing journals.

✓ Surface finish and micro-geometry analysis to ensure proper lubrication.

✓ Comprehensive run-out and straightness checks to prevent engine vibration.

✓ Production Capacity: Dedicated line for heavy-duty engine camshafts.

✓ Lead Time: 45-55 days for forging, machining, grinding, and hardening processes.

✓ Minimum Order: Competitive MOQ for heavy equipment parts distributors and major rebuild facilities.

✓ Packaging: Custom heavy-duty crate packaging with protective coatings to prevent corrosion and physical damage.

✓ Logistics: Secure global freight for high-value engine components.

✓ Detailed specification sheet confirming replacement for 8N3891, 7C3864, and 4P2942.

✓ Installation guidelines including timing procedure and bearing clearance specifications.

✓ Mining & Construction Equipment Rebuilders: Essential component for overhauling 3306 engines in loaders, haul trucks, and excavators.

✓ Power Generation Facilities: Critical for generator set engine overhauls.

✓ Heavy-Duty Truck Engine Shops: Key component for 3306 truck engine rebuilds.

Contact Us:

Whatsapp/Phone: +86158 6849 0970

Skype: robinwanguuu@hotmail.com

Email: newm9992@hotmail.com

karherine@xcgparts.com

Wechat: welchanparts_luke

Website: www.xcgparts.com